PROJECT HORIZON

Project Horizon 2011 Updates here.

All future updates will be posted to the link above. Project Horizon Military update is intended as an informational page to field answers for many of the questions we are receiving regarding breaking tactical technologies as they become declassified from the compiled sources as listed below. We will continue our efforts to bring you the most up to date products and information as they are made available in both the military government and private sectors. Streaming news and updates: ===> MIT Video Update || Phase I Exoskeleton Clip || Gryphon- Synthetic Paratrooper || Future Combat Systems | Nanotech | Exoskeletons | Cyborgs | Military Robots

Topics covered in this discussion include the military systems and tactical concepts agenda for FFW including SA enhancement via integrated full spectrum helmet communications, GPS location and status monitoring, artificial vision magnification, auditory enhancement, advanced theory ballistic protection, Exo-skeleton & Nano-Technologies, and Soldier portable power & cooling systems.

Future Force Warrior (FFW) is the Army’s flagship Science and Technology initiative to develop and demonstrate revolutionary capabilities for the Future Force Soldier and Small Team. A human-centric, integrated system of systems approach is being employed to support the Army transformation into a soldier centric force. The FFW is a major pillar of the Future Force Strategy, complementing the Future Combat System (FCS) and other Future Force programs.

Future Force Warrior (FFW) is the Army’s flagship Science and Technology initiative to develop and demonstrate revolutionary capabilities for the Future Force Soldier and Small Team. A human-centric, integrated system of systems approach is being employed to support the Army transformation into a soldier centric force. The FFW is a major pillar of the Future Force Strategy, complementing the Future Combat System (FCS) and other Future Force programs.

FFW seeks to create a lightweight overwhelmingly lethal, fully integrated combat system including head to toe individual protection, ad-hoc networking, soldier worn power sources, and enhanced human performance. The program is aimed at providing unsurpassed individual and small team lethality, survivability, communications and responsiveness a formidable warrior in an invincible team. FFW will be fully integrated with FCS and other Future Force platforms.

LETHALITY:

FFW interfaces with advanced, lightweight weapons and fire control optimized for urban combat, synchronized direct fire and indirect fire within and across FFW team, and leveraging FCS NLOS/BLOS fires.

SURVIVABILITY:

Lightweight, low bulk, multi-functional, full spectrum protective combat ensemble. Ballistic protection, novel signature management, semi-permeable membrane for CB/wet protection, electro-textile power/data body LAN. On-board physiological/medical sensor suite with enhanced casualty care. Customized voice, tactile, visual and auditory human interface, with integrated laser eye protection.

NETWORKING COMMUNICATIONS/ COLLABORATIVE SITUATIONAL AWARENESS (NC/CSA):

Netted FFW small unit/teams with robust team communications, state-of-the-art distributed and fused (thermal and image intensification) sensors, organic tactical intelligence/collection assets, enhanced situational understanding, embedded training, on-the-move planning, and linkage to other Future Force assets.

MOBILITY, SUSTAINABILITY, AND HUMAN PERFORMANCE:

Unconstrained vertical and lateral movement at full up combat/ assault capability during mission execution. Objective individual soldier load weight of 40 pounds by introduction of lighter weight, multi-functional materials throughout all facets of the combat ensemble, a holistic systems approach, and offloading onto FCS robotic MULEs. Optimized cognitive and physical fight ability.

POWER:

24 hours autonomous individual operation, high density, low weight/volume, reliable, safe power source/system. 72 hours continuous team operations relying on the FCS MULE for recharging/fuel replacement.

Page Contents

- How the Future Force Warrior Will Work by Kevin Bonsor

- Here are the basic components of the final version of the suit:

- Battlefield Awareness

- Future Force Warrior helmet

- Liquid Body Armor

- Exoskeleton

- How Exoskeletons Will Work by Kevin Bonsor

- Morphing Man and Machine

- Challenges of Development

- How Nanotechnology Will Work by Kevin Bonsor

- Building with Atoms

- A New Industrial Revolution

- Future Warrior Concept

- Concepts: Land Warrior

- Land Warrior

- Integration of Computers and Electronics with Textiles for Future Warrior Systems

- Development of Nonwoven Fabrics for Military Applications

- Future Force Warrior Cooling System

- Warrior Individual Cooling System (WICS)

- Portable Vapor-Compression Cooling System (PVCS)

How the Future Force Warrior Will Work by Kevin Bonsor

Wars are evolutionary, with each new conflict bringing more powerful and advanced weaponry. Weapons that yield success on the modern battlefield today can quickly become outdated and ineffective in just a few years. The reality of the battlefield necessitates continuous change in the pursuit to stay a step ahead of the enemy.

Future Force soldiers

To better equip its soldiers, the U.S. Army is developing an advanced infantry uniform that will provide superhuman strength and greater ballistic protection than any uniform to date. Also, using wide-area networking and onboard computers, soldiers will be more aware of the action around them and of their own bodies.

Suiting Up For Battle

With the development of a bionic uniform for its soldiers, the U.S. Army is planning for a change in the logistics of war. Integrated physiological monitoring, enhanced communication and augmented physical strength will give the soldiers of the future the tools they need to overwhelm their opponents simply by donning a hi-tech suit.

There are two phases to the Future Force Warrior program. The first phase involves the deployment of a uniform in 2010 that will meet the Army’s short-term needs, although pieces of the uniform may be deployed earlier. According to Future Force Warrior Equipment Specialist Jean-Louis “Dutch” DeGay, “The Department of the Army has built what’s called design spirals, so roughly every two years, if a piece of technology has matured, we try to get it in the field, rather than waiting until 2010 to field the entire system.” In 2020, the U.S. Army will roll out a suit that integrates nanotechnology , exoskeletons and liquid body armor, all of which exist only in concept now.

Here are the basic components of the final version of the suit:

Helmet – The helmet houses a GPS receiver , radio and the wide- and local-area network connections.

Warrior Physiological Status Monitoring System – This layer of the suit is the closest to the body and contains sensors that monitor physiological indicators, such as heart rate , blood pressure and hydration. The suit relays the information to medics and field commanders.

Liquid Body Armor – This liquid body armor is made from magnetorheological fluid, a fluid that remains in a liquid state until the application of a magnetic field. When an electrical pulse is applied, the armor transitions from a soft state to a rigid state in thousandths of a second.

Exoskeleton – The exoskeleton is made of lightweight, composite devices that attach to the legs and augment the soldier’s strength.

Together, these subsystems combine to create a uniform that informs, protects and enhances the abilities of its wearer. Now let’s take of each of these components separately.

Battlefield Awareness

Prototype 2020 Courtesy Army Natick

The value of enemy reconnaissance depends on how quickly that information can be relayed to the soldier on the battlefield. The soldiers of the future will have more information immediately available to them than ever before.

The Future Force Warrior setup is a significant improvement over current systems. A computer embedded in the suit and located at the base of the soldier’s back will be connected to a local and wide-area network, allowing for data transfer.

DeGay explains it this way:

Essentially, it’s what we call the “borg” effect, to borrow a theme from Star Trek. Everything in the battle space is a sensor, whether that’s a vehicle, rotor wing, fixed wing, aviation vehicle, ground vehicle, individual soldier or unmanned robotic platform. That becomes a sensor that I can track for data. I can send data to it or take data, video or audio from it.

Soldiers will utilize a voice-activated, drop-down screen in the helmet to access information without having to put down their weapons. Embedded in a pair of transparent glasses, the display will appear to the soldier as a 17-inch screen. This screen can display maps and real-time video provided by a forward-positioned scout team, satellite or aircraft. According to DeGay, “We are working to have the graphic user interface inside the computer systems to either replicate computer graphic user interfaces or even Playstation 2/Xbox graphic user interfaces,” because most of today’s soldiers are already familiar with how those systems work. Not only will Future Force Warriors know more about their fellow soldiers, but they also will know more about their own physiological condition. The physiological subsystem of the uniform lies against the soldier’s skin and includes sensors that monitor soldier’s core body temperature, skin temperature, heart rate, body position (standing or sitting) and hydration levels. These statistics are monitored by the soldier and by medics and commanding officers who might be miles away. Knowing the condition of a platoon of soldiers allows commanders to make better strategic decisions. The Future Force Warrior helmet also includes a GPS receiver, providing commanders with exact positioning data on their troops.

Photo courtesy U.S. Army Natick Soldier Center

Future Force Warrior helmet

Another vital component of battle is military communication between soldiers. The Future Force Warrior will use sensors that measure vibrations of the cranial cavity, eliminating the need for an external microphone. This bone-conduction technology allows soldiers to communicate with one another, and it also controls the menus visible through the drop-down eyepiece. The helmet has 360-degree situational awareness and voice amplification.

“What this will allow you to do is to know where that sniper round or mortar round came from, but at the same time it will cancel out noise at a certain decibel so as to not cause damage to the soldier’s ears,” said Robert Atkinson, liaison sergeant, operational forces interface group, Natick Soldier Center.

The situation-awareness technology also allows soldiers to:

detect other soldiers in front of them up to a couple of kilometers away

focus in on a particular sound and amplify it

Powering the entire suit is a 2- to 20-watt microturbine generator fueled by a liquid hydrocarbon. A plug-in cartridge containing 10 ounces of fuel can power the soldier’s uniform for up to six days. Battery patches embedded in the helmet provide three hours of back-up power.

Liquid Body Armor

With advances in ballistics, armies must develop better body armor . One type of modern body armor, first developed in the 1960s, is made out of advanced woven fibers that can be sewn into vests and other soft clothing. More commonly known as Dupont Kevlar®, this is one of the many body armor solutions currently employed by U.S. Forces. Another type of armor, SAPI plates, or “small arms protective insert” plates, are hardened ceramic composite plates inserted into a soldier’s fragmentation protective vest in both the forward and back torso pockets.

Now, scientists are working on a new breed of armor made from magnetorheological (MR) fluids — liquid body armor.

One type of MR fluid consists of small iron particles suspended in silicon oil. The oil prevents the particles from rusting. The fluid transforms from liquid to solid in just milliseconds when a magnetic field or electrical current is applied to it. The current causes the iron particles to lock into a uniform polarity and stack on top of each other, creating an impenetrable shield. How hard the substance becomes depends on the strength of the magnetic field or electrical current. Once the charge or magnetic field is removed, the particles unlock, and the substance goes back to a fluid state.

MR fluid will fill small pockets in the Future Force Warrior uniform fabric. The uniforms will be wired to allow an electrical current to pass through the fabric. The electrical current will be controlled by the onboard computer system and will automatically charge the MR fluid when there is a ballistic threat present.

MIT scientists who are developing the liquid body armor say that it will take five to 10 years to make the substance fully bullet resistant.

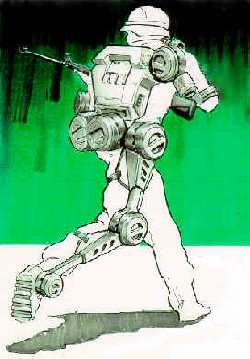

Exoskeleton

Superhuman strength has always been confined to science fiction, but advances in human-performance augmentation systems could give soldiers the ability to lift hundreds of pounds using the effort they would usually use to lift a fraction of that weight.

In the shoulder of the Future Force Warrior uniform is a fabric filled with nanomachines that mimic the action of human muscles, flexing open and shut when stimulated by an electrical pulse. These nanomachines will create lift the way muscles do and augment overall lifting ability by 25 to 35 percent.

“Think of yourself on steroids, holding as much weight as you want for as long as you want,” said Atkinson. “It will also allow a 90 pound male or female to carry a 250 pound male or female off of the battlefield and it wouldn’t feel like they were carrying 250 pounds worth of person.”

The exoskeleton attached to the lower body of the soldier will provide even more strength. The overall exoskeleton will provide up to 300 percent greater lifting and load-carrying capability.

“The Exoskeleton, which is in conjunction with DARPA, will give the soldier more stability,” Atkinson said. “It makes the soldier become a weapons platform.”

With this added strength, weapons can be mounted directly to the uniform system. In the concept uniform (at right), the exoskeleton is the protruding composite material you see below the knee.

The exoskeleton will merge structure, power, control, actuation and biomechanics. Here’s a look at some of the challenges that DARPA has outlined:

Structural materials – The exoskeleton will have to be made out of composite materials that are strong, lightweight and flexible.

Power source – The exoskeleton must have enough power to run for at least 24 hours before refueling.

Control – Controls for the machine must be seamless. Users must be able to function normally while wearing the device.

Actuation – The machine must be able to move smoothly so it’s not too awkward for the wearer. Actuators must be quiet and efficient.

Biomechanics – Exoskeletons must be able to shift from side to side and front to back, just as a person would move in battle. Developers will have to design the frame with human-like joints.

As warfare changes, armies are looking for any advantage they can get against potential enemies. The new Future Force Warrior suit will take human performance to unprecedented levels. Imagine a platoon of soldiers wearing suits that turn an ordinary person into a real, live superhero.

How Exoskeletons Will Work by Kevin Bonsor

Photo courtesy DARPA

Humans aren’t the swiftest creatures on Earth, and most of us are limited in the amount of weight that we can pick up and carry. These weaknesses can be fatal on the battlefield, and that’s why the U.S. Defense Advanced Research Projects Agency (DARPA) is investing $50 million to develop an exoskeleton suit for ground troops. This wearable robotic system could give soldiers the ability to run faster, carry heavier weapons and leap over large obstacles.

Basically, an exoskeleton is a wearable machine that gives a human enhanced abilities. Imagine a battalion of super soldiers that can lift hundreds of pounds as easily as lifting 10 pounds and can run twice their normal speed. The potential of non-military applications is also phenomenal. In 2000, DARPA requested proposals for human performance augmentation systems , and will soon be signing contracts to begin developing exoskeletons. The military agency said that the testing of this new technology is at least a decade away. It will be much longer before soldiers are donning these body amplification systems for battle.

These exoskeletal systems are expected to give soldiers amplified strength and speed, and will also have built-in computers to aid soldiers in navigating foreign territories. Questions still remain about how these machines will be powered and how they will respond to human motion. In this edition of How Stuff WILL Work , we will take a look at how humans will wear these machines and the challenges that researchers must overcome to make them practical for use on the battlefield and for commercial applications.

Morphing Man and Machine

What the exoskeleton program at DARPA plans to do is turn ordinary soldiers into super-troops who can leap tall objects and run at high speeds. This program is still in the early stages, so details of these wearable machines are still very vague. However, DARPA has set some expectations for these exoskeletal machines. Here’s what researchers expect exoskeletons to do for soldiers:

Increase strength – Soldiers will be able to carry more weapons and supplies. By increasing strength, soldiers will also be able to remove large obstacles from their path while marching. It will also enable them to wear heavier body armor and other ballistic protection. In the 1960s, General Electric and the U.S. military co-developed an exoskeleton, named Hardiman , that made lifting 250 pounds feel like lifting 10 pounds.

Increase speed – An average human walks 4 to 6 mph, but soldiers are often expected to carry up to 150 pounds of supplies in their backpacks. Even the best-conditioned troops cannot go very fast carrying that much weight on their backs. It’s not certain how fast DARPA’s exoskeleton will be able to move. An independently civilian developed body amplifier, the SpringWalker , has been tested at speeds faster than 10 mph (16 km/h).

Leap great heights and distances – It’s unclear just how far or high soldiers will be able to jump wearing mechanical suits, but officials would like the machine to give soldiers the ability to leap over obstacles that would ordinarily slow troops down.

Overall, soldiers will benefit from increased endurance when marching long distances over unpredictable terrain. With increased strength, they will also be able to repair heavy equipment that would otherwise be impossible to repair. Experts expect fewer casualties because of increased body armor.

These exoskeletal machines would also be equipped with sensors and Global Positioning System (GPS) receivers. Soldiers could use this technology to obtain information about the terrain they are crossing and how to navigate their way to specific locations. DARPA is also developing computerized fabrics that could be used with the exoskeletons to monitor heart and breathing rates.

If the U.S. military has its way, it will have throngs of super soldiers that can jump higher, run faster and lift enormous weight by strapping these exoskeletons to them. However, developing these devices is expected to take years, if not decades. In the next section, you will learn about some of the obstacles that face researchers charged with developing these exoskeletons.

Challenges of Development

DARPA will not be the first to attempt to build an exoskeletal mechanical body suit. As mentioned previously, GE developed the Hardiman hydraulic and electrical body suit in the 1960s. The problem with that suit is that it was so big and heavy (1,500 pounds) that it wasn’t practical. Today, there are more advanced materials, such as carbon fiber and other mechanisms available that can be used to build a more streamlined exoskeleton. However, the project is not without its challenges.

Photo courtesy DARPA

An artist’s concept of how future soldiers will look when wearing exoskeletal machines.

Five elements will have to come together to make an exoskeleton machine work, including the structure, power, control, actuation and biomechanics. Each of these elements comes with its own set of challenges. Here’s a look at some of the challenges that DARPA has outlined:

Structural materials – The exoskeleton will have to be made out of composite materials that are strong, lightweight and flexible. The material must also be capable of protecting itself and its wearer from enemy fire.

Power source – The exoskeleton must have enough power to run for at least 24 hours before refueling. Power must also be generated by a pack that can be worn by a person. Creating a machine that makes zero noise could be the most difficult task facing exoskeleton developers. The machine will be powered by some type of engine , so how will they prevent that engine from making noise?

Control – Controls for the machine must be seamless. Users must be able to function normally while wearing the device.

Actuation – Designers will have to give the machine the ability to move smoothly, so that it’s not too awkward for the wearer. Like the engine, actuators must be quiet and efficient.

Biomechanics – Will the machines be able to move like a human? Exoskeletons will have to be able to shift from side to side and front to back, just as a person would move in battle. If it lacks that ability, it could be fatal for soldiers wearing the suits. Developers will have to design the frame with joints that can bend like ours.

Military exoskeletons will be some of the most sophisticated machinery ever developed and could also lead to developments in making robots more like humans. Exoskeletons must be able to sense human motion and react to it. They will also need the ability to convert power from an energy source into useable, actuation power to aid its human wearer. The challenges that lay ahead of developers are great, and we will likely see many new devices and innovations developed to make these exoskeletons work.

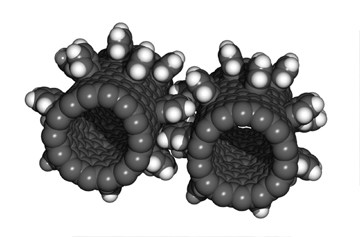

How Nanotechnology Will Work by Kevin Bonsor

In the early 20th century, Henry Ford built a car manufacturing plant on a 2,000-acre tract of land along the Rouge River in Michigan . Built to mass-produce automobiles more efficiently, the Rouge housed the equipment for developing each phase of a car, including blast furnaces , a steel mill and a glass plant. More than 90 miles of railroad track and conveyor belts kept Ford’s car assembly line running. The Rouge model was lauded as the most efficient method of production at a time when bigger meant better.

The size of Ford’s assembly plant would look strange to those born and raised in the 21st century. In the next 50 years, machines will get increasingly smaller — so small that thousands of these tiny machines would fit into the period at the end of this sentence. Within a few decades, we will use these nanomachines to manufacture consumer goods at the molecular level, piecing together one atom or molecule at a time to make baseballs, telephones and cars. This is the goal of nanotechnology . As televisions , airplanes and computers revolutionized the world in the last century, scientists claim that tactical nanotechnology will have an even more profound effect on the next century.

Nanotechnology is an umbrella term that covers many areas of research dealing with objects that are measured in nanometers . A nanometer (nm) is a billionth of a meter, or a millionth of a millimeter. In this edition of How Stuff Will Work , you will learn how nanomachines will manufacture products, and what impact nanotechnology will have on various industries in the coming decades.

Building with Atoms

Atoms are the building blocks for all matter in our universe. You and everything around you are made of atoms. Nature has perfected the science of manufacturing matter molecularly. For instance, our bodies are assembled in a specific manner from millions of living cells . Cells are nature’s nanomachines. Humans still have a lot to learn about the idea of constructing materials on such a small scale. Consumer goods that we buy are made by pushing piles of atoms together in a bulky, imprecise manner. Imagine if we could manipulate each individual atom of an object. That’s the basic idea of nanotechnology, and many scientists believe that we are only a few decades away from achieving it.

Photo courtesy NASA, Ames

Nanogears no more than a nanometer wide could be used to construct a matter compiler, which could be fed raw material to arrange atoms and build a macro-scale structure.

Nanotechnology is a hybrid science combining engineering and chemistry. Atoms and molecules stick together because they have complementary shapes that lock together, or charges that attract. Just like with magnets, a positively charged atom will stick to a negatively charged atom. As millions of these atoms are pieced together by nanomachines, a specific product will begin to take shape. The goal of nanotechnology is to manipulate atoms individually and place them in a pattern to produce a desired structure. There are three steps to achieving nanotechnology-produced goods:

- Scientists must be able to manipulate individual atoms . This means that they will have to develop a technique to grab single atoms and move them to desired positions. In 1990, IBM researchers showed that it is possible to manipulate single atoms. They positioned 35 xenon atoms on the surface of a nickel crystal, using an atomic force microscopy instrument. These positioned atoms spelled out the letters “IBM.” You can view this nano-logo on this page .

- The next step will be to develop nanoscopic machines, called assemblers , that can be programmed to manipulate atoms and molecules at will. It would take thousands of years for a single assembler to produce any kind of material one atom at a time. Trillions of assemblers will be needed to develop products in a viable time frame.

- In order to create enough assemblers to build consumer goods, some nanomachines, called replicators , will be programmed to build more assemblers.

Trillions of assemblers and replicators will fill an area smaller than a cubic millimeter, and will still be too small for us to see with the naked eye . Assemblers and replicators will work together like hands to automatically construct products, and will eventually replace all traditional labor methods. This will vastly decrease manufacturing costs, thereby making consumer goods plentiful, cheaper and stronger. In the next section, you’ll find out how nanotechnology will impact every facet of society, from medicine to computers.

A New Industrial Revolution

In January 2000, U.S. President Bill Clinton requested a $227-million increase in the government’s investment in nanotechnology research and development, which included a major initiative called the National Nanotechnology Initiative (NNI). This initiative nearly doubled America ‘s 2000 budget investment in nanotechnology, bringing the total invested in nanotechnology to $497 million for the 2001 national budget. In a written statement, White House officials said that “nanotechnology is the new frontier and its potential impact is compelling.”

About 70 percent of the new nanotechnology funding will go to university research efforts, which will help meet the demand for workers with nanoscale science and engineering skills. The initiative will also fund the projects of several governmental agencies, including the National Science Foundation , the Department of Defense , the Department of Energy , the National Institutes of Health , NASA and the National Institute of Standards and Technology . Much of the research will take more than 20 years to complete, but the process itself could touch off a new industrial revolution. Nanotechnology is likely to change the way almost everything, including medicine, computers and cars, are designed and constructed. Nanotechnology is anywhere from five to 15 years in the future, and we won’t see dramatic changes in our world right away. But let’s take a look at the potential effects of nanotechnology on military tactical gear:

- The first products made from nanomachines will be stronger fibers. Eventually, we will be able to replicate anything, including diamonds , water and food. Famine could be eradicated by machines that fabricate foods to feed the hungry.

- In the computer industry, the ability to shrink the size of transistors on silicon microprocessors will soon reach its limits. Nanotechnology will be needed to create a new generation of computer components. Molecular computers could contain storage devices capable of storing trillions of bytes of information in a structure the size of a sugar cube.

- Nanotechnology may have its biggest impact on the medical industry. Patients will drink fluids containing nanorobots programmed to attack and reconstruct the molecular structure of cancer cells and viruses to make them harmless. There’s even speculation that nanorobots could slow or reverse the aging process, and life expectancy could increase significantly. Nanorobots could also be programmed to perform delicate surgeries — such nanosurgeons could work at a level a thousand times more precise than the sharpest scalpel. By working on such a small scale, a nanorobot could operate without leaving the scars that conventional surgery does. Additionally, nanorobots could change your physical appearance. They could be programmed to perform cosmetic surgery, rearranging your atoms to change your ears, nose, eye color or any other physical feature you wish to alter.

- Nanotechnology has the potential to have a positive effect on the environment. For instance, airborne nanorobots could be programmed to rebuild the thinning ozone layer. Contaminants could be automatically removed from water sources, and oil spills could be cleaned up instantly. Manufacturing materials using the bottom-up method of nanotechnology also creates less pollution than conventional manufacturing processes. Our dependence on non-renewable resources would diminish with nanotechnology. Many resources could be constructed by nanomachines. Cutting down trees, mining coal or drilling for oil may no longer be necessary. Resources could simply be constructed by nanomachines.

- The promises of nanotechnology sound great, don’t they? Maybe even unbelievable? But researchers say that we will achieve these capabilities within the next century. And if nanotechnology is, in fact, realized, it might be the human race’s greatest scientific achievement yet, completely changing every aspect of the way we live.

Future Warrior Concept

Overview:

The future is always uncertain, but by applying logic and imagination to current situations and technologies, a conceptual representation of how soldiers might be equipped in the distant future has been developed. This conceptualization is not U.S. Army doctrine, nor is it intended to answer every question raised by the Army After Next. It is intended to raise questions, stir imaginations, and start dialogue about how best to serve and equip our warfighters in the near future.

Description:

The Future Warrior Concept will be a completely integrated system which will be tailored to each individual, from an electro-spun Combat Uniform to a biomechanically engineered Headgear Subsystem. There are 6 major subsystems included in the concept:

- The Headgear Subsystem , which we describe as Information Central, is the situational awareness hub of the system. It would include Integrated tactical processing (e.g., maps, routes, SA data); 180° emissive visor display; High data rate (GB/sec) communications; Microelectronic/optics combat sensor suite that provides 360° situational awareness; Integrated small arms protection in selected locations.

- The Combat Uniform Subsystem , which we describe as Survivability Central, contains three layers: the Protective Outer Layer, the Power Centric Layer, and the Life Critical Layer.

- The Weapon Subsystem , Lethality Central, permits direct and indirect target engagements. The weapon weighs 5 pounds, and combines 5 tubes of soft-launched, 15mm intelligent seeker munitions and 1 tube of stacked 4.6mm kinetic energy projectiles for close quarter combat.

- The Warfighter Physiological Status Monitor (WPSM) Subsystem collects information on the vital signs (core temperature, skin temperature, heart rate, blood pressure) hydration state, stress level (mouth sensors), thermal state, sleep status, and workload capacity of the warrior. The WPSM can also recommend remote triage care needed.

- The Micro-climate Conditioning Subsystem , a network of narrow tubing built into the material of the Life Critical Layer that provides 100 watts of heating or cooling to the warrior.

- The Power Subsystem , Duration Central, consists of a 2- to 20-watt Micro Turbine fueled by a liquid hydrocarbon. Ten ounces of fuel, contained in a lightweight plug-in cartridge, powers the soldier for up to 6 days. Polymeric nanofiber battery patches embedded in the headgear and weapon provide back-up power for three hours.

Concepts: Land Warrior

Capabilities

The Land Warrior system enhances the soldier’s lethality, survivability, mobility, situational awareness and sustainability.

Land Warrior includes everything a soldier wears or carries integrated into a fighting system. The Land Warrior system integrates functionality that addresses the soldier system domains of lethality, mobility, survivability, command and control, sustainability, and training. The system is modular, permitting the individual soldier to tailor their combat load based on unique mission requirements.

With the Land Warrior system, each soldier is always able to answer four key questions:

- Where am I?

- Where are my buddies?

- Where is the enemy?

- What does my leader expect me to do?

The Land Warrior system includes:

- Weapons

- Sensors

- Laser rangfinder

- Displays

- Integrated load carrying equipment

- Clothing

- Helmet

- Speaker and microphone

- Optical display

- Computer

- Navigation equipment

- Squad communications

- Batteries and power management system

Leader communications and display

Land Warrior

System Features

System Features

- Enables total integration into the digital battlefield

- Integrated with Stryker Brigade Combat Team vehicles for en-route situational awareness updates and battery recharging

- Integrated system for weight and power reduction, yet tailorable for operational missions

- System architecture and modularity allows for future upgrades in technology and capability

- Enables transition to Army Future Combat Systems interoperability

- Path for technology insertions from Objective Force Warrior and other sources

- Enables transition to Army Future Combat Systems interoperability

Newer Features of the Land Warrior System Include:

- Provides dismounted soldier combat identification for enroute situational awareness and power recharge to reduce ‘friendly fire’ incidents

- Commanders Digital Assistant leader planning tool

- Weight and power reduction

Scalable and tailorable for operational missions

Systems

Electro-Textiles

Integration of Computers and Electronics with Textiles for Future Warrior Systems

Overview:

Natick Soldier Center has a high interest in integrating electronic capabilities and optical components with textile materials and soldier equipment. Future Warrior Systems already being planned have heads up displays, wireless weapons, global positioning, chemical detectors, battery power, physiological status sensors, and combat ID, all linked to the Warrior’s personnel computer to assist in situational awareness and understanding. Electronic devices are being miniaturized for personal use; however, limited technologies exist to integrate electronics into clothing. Combat clothing materials are currently passive. Consequently, the integration of electronics into the Soldier System will provide enhanced capabilities by providing real-time information to the soldier on the battlefield. Active intelligent textile systems have the capacity of improving the Warrior’s performance by sensing and responding to a situational combat need allowing the Warrior to continue his mission without distraction. The overall solution is to convert passive combat clothing into active materials that provide electronic/optical power and data transmission to the on-body computer, batteries, displays, and sensors, and several integrated antennas for near and remote communications.

Description:

Personal area network cables and connectors for attaching sensors and computer peripheral devices, as well as a variety of visually concealed antennas for near and remote communications need to be integrated into the Warrior’s clothing and equipment to reduce weight and bulk of the current electronic system being hung on the Warrior. Other areas of interest include the integration of solar and other power generating components and conductive plastic batteries into textiles. Customers include PM-Soldier, SOCOM, and Objective Force Warrior.

Status:

Funding for this effort has come from a variety of sources, including Army S&T, SBIR, and Manufacturing Technology programs depending on the maturity of the individual technology.

A future soldier system electronic network has been mapped that will serve as the soldier’s electronic backbone. A prototype flat USB bus and connectors integrated into narrow fabrics have been successfully developed, as well as an integrated wearable combined Soldier/GPS antenna. Current efforts also include a suite of wearable antennas, textile embedded electrical/optical zipper and rotational snap connectors, other flat textile based networks and ergonomic connectors, textile-based antenna radiators for long-distance and multi-frequency antennas, manufacturing techniques to integrate electrical/optical conductors into various textile constructions and stitchless seams, pin-less flat connectors, and a pressure sensitive textile-based computer input device.

Development of Nonwoven Fabrics for Military Applications

Overview:

The United States Marine Corps has taken the initiative to develop state-of-the-art nonwoven composite fabric technology for use as alternate fabric application for Combat Utility Uniforms (CUU’s), equipage, shelters etc. This effort is being conducted via a Small Business Innovative Research (SBIR) contract. The objective of the SBIR is to utilize latest nonwoven technology to enhance performance and reduce lifecycle costs for combat type clothing. Concept includes development of lightweight composite material that offers high durability, high breaking and tearing strength, breathability, and cost reduction to replace current woven uniform material. Included is to design a Fire Retardant (FR) fabric and heavy-duty fabric for tentage and equipage applications.

Description:

Typical woven fabrics use old textile technologies that are outdated and generally outsourced to other countries. It uses twisted yarn construction that has poor insulation, filtration and barrier properties, whereas nonwovens are only a few decades old and offer innovation and technological growth. Nonwovens are fabricated with finer individual fibers that are bonded and/or entangled to supply better insulation, filtration and barrier properties. The strength of nonwoven fabrics is that they can be engineered with specific properties but with higher production rate, wider width up to 120 inches and lower costing with potential for full automation.

Phase I studies indicated that nonwoven composite fabrics can be made 25% lighter and stronger than current woven military uniform fabrics. In addition, they can be made to exhibit over three times the air permeability or breathability of the current woven military uniform fabrics.

Phase II uniform fabric would offer enhanced abrasion resistance, develop a fire and chemical/biological resistant fabric and offer combination water repellent/moisture absorbent composite fabric.

Status:

Successful commercialization is the future of nonwovens. Getting people to accept nonwovens for clothing and general applications will be the key to success. Thus far, nonwovens are generally perceived as disposables with a harsh stiff hand and weak in nature. The goal of this SBIR is to break out of this mode and prove the concept through use of military applications.

Future Force Warrior Cooling System

Overview:

The FFW-CS is a lightweight, man-portable, liquid circulating microclimate cooling system, designed to provide heat stress relief to Warfighters wearing Body Armor and/or Chemical/Biological (CB) protective ensembles in desert and jungle environments.

Description:

The FFW-CS chills and circulates cool water through a tube-type heat-transfer garment. The chilled circulating fluid in the tubing network transfers metabolic heat from the Warfighter’s body and rejects it to the ambient environment via its condenser.

Specifications:

- Cooling Power: 120 Watts in a 95°F environment

- Electrical Power Consumption: 35 watts (time weighted average)

- Weight: 3.5 pounds (excluding power source)

- Volume: 1.0 liter

- Coolant Fluid Temperature: 77°F

- Refrigerant: R134A

- Cylindrical Design

Status:

The Future Force Warrior Cooling System is being developed under Natick Soldier Center ‘s Microclimate Cooling Program. A fully functional demonstration prototype Cooling System is expected in mid 2008.

Warrior Individual Cooling System (WICS)

Overview:

The WICS is a lightweight, man-portable, liquid circulating microclimate cooling system, designed to provide heat stress relief to Soldiers encapsulated in the Future Force Warrior (FFW) Chemical/Biological (CB) ensemble in hot environments.

Description:

The WICS is a vapor compression cycle cooler which pumps a chilled fluid through a tube-type heat transfer garment. Metabolic heat is transferred, by conduction, from the Soldier to the chilled circulating fluid in the tubing network, and rejected to the ambient environment via the WICS’ condenser.

Specifications:

Cooling Power: 120 Watts in a 95° F environment

Electrical Power Consumption: <50 watts (24 Volts DC/2 Amps)

Weight: 3.5 pounds (excluding power source)

Volume: 1.5 liters (~11.2 cm dia x 15.2 cm)

Coolant Fluid Temperature: 77° F

Refrigerant: R134A

Cylindrical Design

Status:

The Warrior Individual Microclimate Cooling System is being developed under a phase two Small Business Innovative Research (SBIR) Program by Rini Technologies, Inc. This system will represent a 48% reduction in volume compared to the previous state-of-the-art, portable, microclimate cooling system. A fully functional prototype is expected in May 2006.

Portable Vapor-Compression Cooling System (PVCS)

Overview:

The Portable Vapor-Compression Cooling System (PVCS) is a self-contained man-portable microclimate cooling system designed to provide wearers of insulative protective clothing with cooling to reduce the effects of heat stress.

Description:

The PVCS consists of the Refrigeration Unit, Battery Module, Heat Transfer Garment, and accessory tether lines. The Refrigeration Unit chills the coolant and pumps it through the External Coolant Tether Line and into the Heat Transfer Garment. Metabolic heat from the body is transferred to the coolant as it flows through the network of tubing in the Heat Transfer Garment. The coolant then flows back to the Refrigeration Unit where the heat is rejected. The Battery Module can be disconnected and detached from the Refrigeration Unit if a DC power supply is available.

Specifications:

Cooling capacity (Battery Mode): 1200 watt-hours (300 watts cooling rate)

Comfortable coolant temperature delivered at 65°-70°F

Four-hour duration on batteries, indefinitely on 24-28 volt vehicle power

Compact size (Refrigeration Unit 10.125 x6.625 x6.25, Battery Module 10.25 x6.875 x6.25)

Full body cooling through liquid cooling shirt, pants, & hood

Energy efficient (6 amps max. at 24 volts)

Refrigeration Unit Type: Vapor Compression (HFC, R-134a refrigerant)

Battery Module: Four BA5590 lithium sulfur dioxide batteries

Refrigeration Unit Weight: 10 lbs.

Battery Module Weight: 11 lbs.

Heat Transfer Garment (Shirt, pants, and hood) Weight: 6 lbs.

Status:

The PVCS has been favorably evaluated in heat stress induced physiological studies in climatically controlled chambers. Currently, the PVCS is being adapted for use on rotary wing aircraft.

Prototype 2030 Courtesy RM

RangerMade Military Tactical gear consultants would like to extend special thanks to Prof. Kenneth Rutlege and Capt. Madison Beckett for their continued efforts in support of Project Horizon. Thank you, and great work!

Sources:

Future Force Warrior (FFW) – U.S. Army Natick Soldier Center

http://www.natick.army.mil/soldier/wsit/

General Dynamics

http://www.generaldynamics.com/

MIT’s Institute for Soldier Nanotechnologies (ISN)

http://web.mit.edu/isn/

Future Force Warrior Exhibits Super Powers (American Forces Press Service, June 27, 2004 )

http://www.defenselink.mil/news/Jul2004/n07272004_2004072705.html

Instant Armor (ScienCentralNews)

http://www.sciencentral.com/articles/view.php3?article_id=218392121&language=english

Army scientists, engineers develop liquid body armor (Army News Service, April 21, 2004 )

http://www.military.com/NewsContent/0,13319,usa3_042104.00.html

1st Lieutenant John H. Frushour, USMC, 24th Marine Expeditionary Unit

Contacts: NATICK SOLDIER CENTER

Future Force WarriorTechnology Program Office

Technical inquiries:

508-233-5436

Media inquiries:

Public Affairs Office

508-233-5340